Prodotti & Servizi - Reflow Oven Volumi Alti

Azienda

I Prodotti

Pick & Place

Reflow Oven

Vapour Phase

Screen Printer

Solder Wave

Selective Soldering

Handling

Automatic Optical Inspection

Materiali di Consumo

Attrezzature

Usati & Occasioni

Galleria Immagini

Contatti

Rappresentanze

Privacy

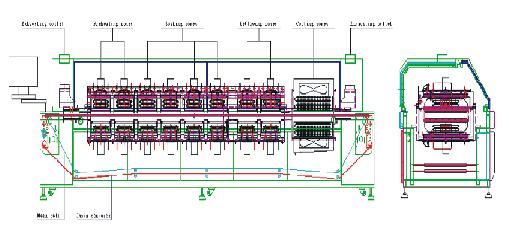

Forni di rifusione serie SF ad azoto

per medie - alte produzioni

(ad aria calda forzata 7-8-10 zone top e bottom)

When will you need SF series Lead-free reflow oven?

a) Production quantity is among 800-1500 pieces/8hours (Take 300mmX300mm as reference).

b) Tough requirement for the soldering quality. Just like mobile PCB board.

c) Can upgrade to N2 feeding system.

d) Can upgrade with CBS system or Dual rail system.

e) CE needed.

Lead-Free Facts

Lead-free profiles require a higher peak temperature, which leaves manufacturers with a much smaller margin for error when it comes to reflowing boards. Tin/lead solder melting temperature is 183 °C, allowing peak temperatures to be set at 210 °C--a safe 50 °C away from heat levels that can be dangerous to the component. Lead-free solders reach liquids at 217 °C, requiring set peak temperatures of 240 to 250 °C. The margin of safety for components narrows to a mere 10 to 20 °C--lead-free soldering is thus less forgiving of temperature fluctuations. Many older reflow ovens just don't have the stringent temperature control required for safe, reliable lead-free soldering. The perfect oven for lead-free solders has higher convection rates and precise temperature control. Introducing the SF series designed specifically to accommodate lead-free solders, and can be updated to feed Nitrogen. If your factory has a very large capacity, this type is a good choice.   Advanced Mechanical Structure a) Adopting forced air convection, hot air spray to PCB well-proportioned under the work of static pressure.

The landscape orientation deviation is under +/-2 °C.The tolerance of near temperature zone reach 100 °C, conjugating the stainless steel inner, meet the requirement of lead-free.

b) Specially designed motor with long shaft, Cwork smoothly and without noise, extra warranty for it c) Specially designed heater which made of Ni filament; Because of the high heat efficiency and little wind drag-index, it have a good performance on heat exchange so to save power

d) Raising temperature in high rateCit's cost only 15 minutes to raise temperature from ambient to 24 °C

e) The upper-cover of the oven is raised by two electrical screw pole safety stick so it is convenient for cleaning inside. f) The tracks are made of special aluminum alloy with high rigidity, accuracy and intensity with auto lubricant filling systems. g) Industrial cooling chiller was configured. Make sure there's a good effect about cooling rate to meet lead-free requirement.

h) Flux management system is very helpful to keep machine clean.

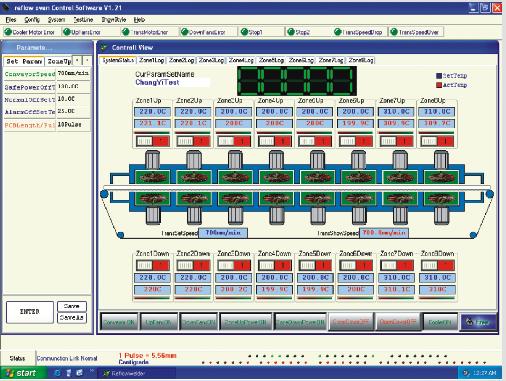

Outstanding Controlling System

a) Self-developed controller, PC and on-line UPS form a stable, safe and efficient controlling system. The self-developed controller is specially design for the lead-free wave solder machine and lead-free reflow oven. Compare with PLC, it have quicker response, better compatible, more powerful ability for future extension. Adopting industrial computer and Germany KETE solid status relay, according PID precision counting to control heating capacity, make sure temperature accuracy is under 1, Suitable for the soldering of BGA, CSP components.

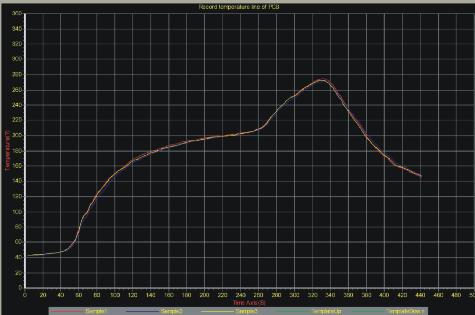

b) Only famous electric parts are adopted in this machine. All these parts are CE certificated. c) Powerful software provides in-line temperature test function and can save and print temperature

profile anytime. Automatically monitoring and displaying the working condition of the oven.

d) Adopted SANTAK ON-LINE UPS to ensure the industrial computer and mesh belt still work when accidental power off. So to protect the PCB in the oven can be carried out safety.

e) PCB count and chain lubricate automatically. f) Authorized windows2000 system, high stability.   operator interface panel profiling system

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||